Data Asas

Jenis Asas:

1. Gaya pengalir tunggal bertebat

2. Gaya konduktor berkembar

3. Lengan hujung kord tidak berpenebat

Ciri-ciri

Jumlah keratan rentas: 0.25~150mm²

Pengekodan warna dan dimensi tiub kepada DIN 46228, bahagian 4(0.5~50mm²)

Bebas halida, kalis api boleh diterima

Tahan haba kepada 105℃(PP) 120℃ (PA)

Bahan:

99% Kuprum tulen

Sintetik: Polipropilena(PP), Poliamida(PA)

Permukaan

Bersalut timah untuk melindungi daripada kakisan

Maklumat pesanan

Kini juga tersedia dalam kotak plastik berguna untuk keperluan yang lebih kecil.Dalam keadaan biasa kami tidak mempunyai keperluan MOQ untuk pembungkusan beg.

Data teknikal

Bahan Konduktif (kecuali Julat Sambung Pantas)

| Tembaga | 99.9% tulen |

| Kekuatan Tegangan | 200MPa |

| Penarafan Mulur | 35% |

| Keadaan Logam Akhir | Sebahagian daripada produk anil |

| Kandungan Oksigen | 50ppm maks |

|

|

|

| Tembaga | 30% Zink 70% Kuprum |

| Kekuatan Tegangan | 580 Mpa |

| Penarafan Mulur | 6% min |

| Keadaan Logam Akhir | Sebahagian daripada produk anil |

|

|

|

| bahan | timah |

| Kandungan Tin | 99.90% |

| Logam Lain | Plumbum + Antimoni |

| Ketebalan Penyaduran | 1.5 mikron |

|

|

|

| Kekonduksian Umum | 98.5% IACS |

| Kerintangan Jumlah | 1.738 mikro-ohm cm |

|

|

|

| bahan | PVC untuk semua kecuali nilon 6 atau nilon 66 – untuk IQC |

| Voltan kerosakan | 1.5 k V(min) |

| Rintangan penebat | Di atas 100 meg ohm |

| Voltan kerja | Sehingga 300V AC/DC |

|

|

|

| Pra-Penebat | -40 ℃ hingga + 150 ℃ |

| Tembaga | 145 ℃ |

| bersalut timah | 160 ℃ |

SPESIFIKASI

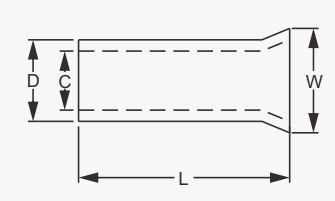

| Keratan rentas (mm²) | barang No. | Dimensi (mm) | AWG |

| Keratan rentas (mm²) | barang No. | Dimensi (mm) | AWG | ||||||

| L | W | D | C |

| L | W | D | C | ||||||

| 0.25 | EN0206 | 6 | 1.5 | 1.1 | 0.8 | #26 |

| 10 | EN10-18 | 18 | 5.8 | 4.9 | 4.5 | #8 |

| EN0208 | 8 |

| EN10-20 | 20 | ||||||||||

| 0.34 | EN0306 | 6 | #24 |

| EN10-25 | 25 | ||||||||

| EN0308 | 8 |

| 16 | EN16-12 | 12 | 7.2 | 6.2 | 5.8 | #6 | |||||

| 0.5 | EN0506 | 6 | 1.7 | 1.3 | `1.0 | #22 |

| EN16-16 | 16 | |||||

| EN0508 | 8 |

| EN16-18 | 18 | ||||||||||

| EN0510 | 10 |

| EN16-20 | 20 | ||||||||||

| EN0512 | 12 |

| EN16-22 | 22 | ||||||||||

| 0.75 | EN7506 | 6 | 1.9 | 1.5 | 1.2 | #20 |

| EN16-25 | 25 | |||||

| EN7508 | 8 |

| 25 | EN25-12 | 12 | 9.1 | 7.9 | 7.5 | #4 | |||||

| EN7510 | 10 |

| EN25-16 | 16 | ||||||||||

| EN7512 | 12 |

| EN25-18 | 18 | ||||||||||

| 1.0 | EN1006 | 6 | 2.2 | 1.7 | 1.4 | #18 |

| EN25-22 | 22 | |||||

| EN1008 | 8 |

| EN25-25 | 25 | ||||||||||

| EN1010 | 10 |

| 35 | EN35-16 | 16 | 10.2 | 8.7 | 8.3 | #2 | |||||

| EN1012 | 12 |

| EN35-20 | 20 | ||||||||||

| EN1018 | 18 |

| EN35-25 | 25 | ||||||||||

| 1.5 | EN1508 | 8 | 2.5 | 2.0 | 1.7 | #16 |

| 50 | EN50-12 | 12 | 12.7 | 10.9 | 10.3 | #1 |

| EN1510 | 10 |

| EN50-18 | 18 | ||||||||||

| EN1512 | 12 |

| EN50-22 | 22 | ||||||||||

| EN1518 | 18 |

| EN50-25 | 25 | ||||||||||

| 2.5 | EN2506 | 6 | 3.3 | 2.6 | 2.3 | #14 |

| 70 | EN70-22 | 22 | 15.8 | 14.3 | 13.5 | 2/0 |

| EN2508 | 8 |

| EN70-25 | 25 | ||||||||||

| EN2510 | 10 |

| EN70-32 | 32 | ||||||||||

| EN2512 | 12 |

| 95 | EN95-25 | 25 | 17.3 | 15.6 | 14.8 | 3/0 | |||||

| EN2518 | 18 |

| EN95-30 | 30 | ||||||||||

| 4 | EN4009 | 9 | 3.9 | 3.2 | 2.8 | #12 |

| EN95-34 | 34 | |||||

| EN4012 | 12 |

| 120 | EN120-30 | 30 | 20.2 | 17.7 | 16.7 | 4/0 | |||||

| EN4018 | 18 |

| EN120-34 | 34 | ||||||||||

| 6 | EN6010 | 10 | 4.7 | 3.9 | 3.5 | #10 |

| EN120-38 | 38 | |||||

| EN6012 | 12 |

| 150 | EN150-32 | 32 | 23 | 20.6 | 19.6 | 250/300 | |||||

| EN6018 | 18 |

| EN150-40 | 40 | ||||||||||

| 10 | EN10-12 | 12 | 5.8 | 4.9 | 4.5 | #8 |

| 185 | EN185-32 | 32 | 23.9 | 21.4 | 20.2 | 300/350 |

| EN10-16 | 16 |

| EN185-40 | 40 | ||||||||||